The manufacturing space is under constant pressure to increase productivity while keeping costs low. As more manufacturers lean into utilizing the Internet of Things (IoT) and connected devices, there is a noticeable increase of process efficiency and productivity.

IoT, or connected devices, refers to devices connected to a network that collect, share and act on information. This technology can facilitate a safe and secure work floor by monitoring vehicle accidents, employee absences, injuries, and other machinery malfunctions.1

Manufacturers can implement IoT by increasing their use of sensors. Responsive sensors on machines can alert workers to a machine failure or breakdown. Sensors can also be used for predictive maintenance, to alert workers when a machine needs servicing. Using sensors in this way allows for a more targeted maintenance schedule, which can improve operations and potentially lower costs.

Additionally, there are a variety of smart devices that can improve productivity and safety on a manufacturing floor.

- Connected cameras (imagery) to detect risk in workplaces. This can help improve safety, quality and productivity.

- Wearables worn on the body to help reduce the risk of injury and improve workers’ safety.

- Water damage prevention technology to monitor water, temperature, humidity and flow. This can help reduce the risk of property damage and business interruption from accidental water events.

- Telematics, which are a high-tech combination of information technology and telecommunications. They enable real-time data collection, analysis and transfer.

Many industries use IoT devices to improve efficiencies and safety. In fact, the number of IoT devices in use is projected to rise to around 50 billion devices by 2030.2

As more IoT devices are incorporated into day-to-day operations, companies can see a decrease in unplanned halts to production, which lead to monetary losses. 82% of companies have experienced unplanned downtime, which can cost a company as much as $260,000 an hour.3

IoT devices have various sensors that can monitor the temperature, vibration, voltage and currents. These sensors can help with early warning signs of any predicted malfunctions, which in turn, creates a safer workplace.

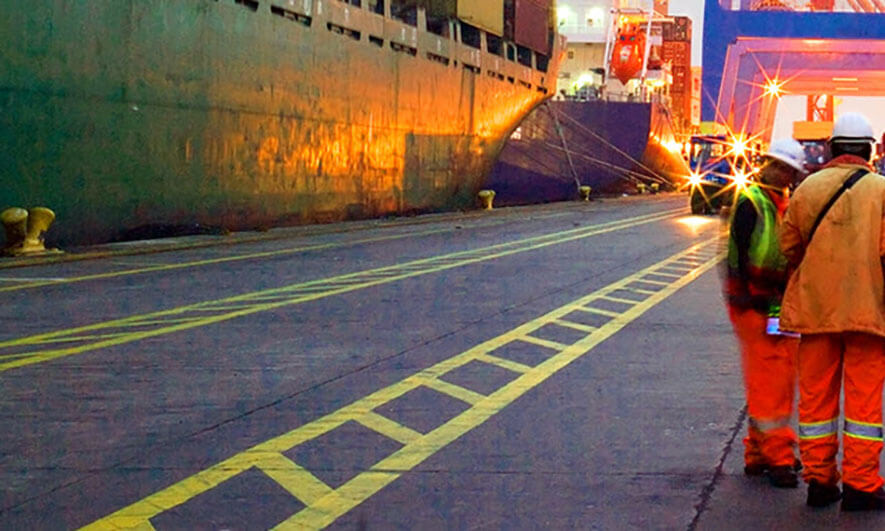

Using Imagery in Industrial IoT

IoT imagery relies on existing cameras and connected artificial intelligence software to monitor workers in order to identify safety risks. When unsafe behavior is detected, it can trigger real-time alerts to promote a safer work environment, including:

- Ensuring proper PPE is being worn

- Abiding by forklift zones and speed limits

- Ensuring proper clean up to prevent slip and fall accidents

- Identifying and evaluating near misses

Imagery can also be used to identify incidents as they happen, like slips and falls.

Using Wearable Technology in Smart Manufacturing

People use wearable technology, such as fitness trackers, on a daily basis to personally track their goals and overall health.

On the job, wearables can help improve worker safety and reduce job-related injuries and illnesses. This can help lower the number of workers’ compensation insurance claims.

Manufacturers can use wearable technology to:

- Improve ergonomics

- Monitor environmental conditions

- Track employee location during a crisis

- Detect falls

Some wearable devices that can help keep manufacturing workers safe include:

- Belts to track movement in the workplace, such as bends and twists, to help improve ergonomics.

- Gloves, which record data on how workers use their hands and wrists on the job.

- Armbands that track repetitive pushing or pulling and that monitor environmental conditions, air quality and noise levels.

- Straps worn around the chest or other body part to monitor ergonomics or detect worker falls.

Connected devices can help predict and prevent potential insurance losses. They can also raise awareness around safety risks in manufacturing workplaces and provide you valuable insights with the data collected. The goal is to use IoT solutions to help solve your most disruptive business problems.

To learn more about the The Hartford’s IoT Innovation Lab and solutions to lower your total cost of risk, email our IoT Innovation Lab or reach out to your Hartford representative.

1,3 “How is IoT Used in Manufacturing: 8 Use Cases and Upcoming Trends,” Imaginovation Insider, May 2023.

2 “IoT In 2023 And Beyond,” Tech Informed, March 2023

The information provided in these materials is intended to be general and advisory in nature. It shall not be considered legal advice. The Hartford does not warrant that the implementation of any view or recommendation contained herein will: (i) result in the elimination of any unsafe conditions at your business locations or with respect to your business operations; or (ii) be an appropriate legal or business practice. The Hartford assumes no responsibility for the control or correction of hazards or legal compliance with respect to your business practices, and the views and recommendations contained herein shall not constitute our undertaking, on your behalf or for the benefit of others, to determine or warrant that your business premises, locations or operations are safe or healthful, or are in compliance with any law, rule or regulation. Readers seeking to resolve specific safety, legal or business issues or concerns related to the information provided in these materials should consult their safety consultant, attorney or business advisors. All information and representations herein are as of November 2023.